- sales@indiaforging.com

-

+91-98817-01007 /

+91-253-2310221 / 2310275

Products & Specifications

Our Products

Our main products are Aluminum forgings, Copper forgings.

We are involved in giving an extensive range of forged components at reasonable rates to our customers. These forged components are fabricated with latest technology that ensures optimum efficiency of these components. Our quality products have earned a place for themselves in the highly competitive market.

All of our forged products are project managed so that the inspection and quality requirements are monitored for perfection.

Product Gallery

Capacity Range

Material

Aluminium

Maximum Weight

25 Kgs.

Alloys

Medium & High Strength Alloys Confirming to British 1472, DIN 1749 & ASTM (B-247) standards.

Material

Copper

Maximum Weight

15 Kgs.

Alloys

High Conductivity Coppers, Electrolytic Copper and Brasses.

Aluminium Forgings

The material we use the most for forging is Aluminium a modern material for modern solutions for today and tomorrow. We provide quality aluminium forging alloys. Aluminium drop forged pieces will always offer the most economic solution when, in addition to light weight, such factors as strength, appearance and recycling potential are also important. We specialize in aluminium drop forged pieces. We can employ any aluminium alloy (ex - HE12, HE15, HE30, 6061, 6063 and others) according to the demands of the individual assignment. We carry out production in small, medium and large batch quantities with an individual weight of upto 5 kilograms. We do closed die forgings using the most modern Friction Screw Presses and Drop Hammers.

Copper Forgings

We forge Electrolytic Copper which is generally used in Electrical and Switchgear Industry. We supply fully machined copper forgings. We are also able to supply these components in different surface finishes. We manufacture copper forgings ranging from 200 Grams to upto 15 Kilograms.

Copper Forging is the forging process utilizing copper as the forging material. Copper forgings are common and provide near-net shape parts with minimal waste. Most copper alloys have good plasticity at room temperature and high temperature, and can be forged smoothly. Even in the presence of tensile stress, they still have enough plasticity

Copper forgings are corrosion resistant and pressure tight, and have a wide range of industrial application, specified for high pressure liquid and gas handling applications such as fittings, plumbing hardware, refrigeration components and commercial valves

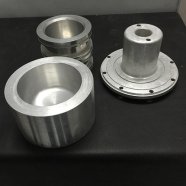

Machined Components

We not only forge aluminium and copper forgings but also offer a comprehensive processing service. By using complex CNC systems and special machines, we offer a top quality finished machined component to our clients. We undertake very complex machining and plating processes for various forged components. If the customer wishes, we can also provide appropriate surface processing procedures and assemble our forged parts into components and sections that are ready for installations or assemblies.

Depending upon the shape, precision & type - forgings are produced under Hammer & Press for closed die blocker type & precision forgings respectively.

We can undertake small batches of Close Die Forgings in Ferrous and Non Ferrous metals with very short lead times for the development of tools and dies. All Forgings are supplied in the required Heat Treated Condition. Machining and Finishing operations can also be carried out and forgings supplied in the ready to use/assemble condition.

Please send us your queries or requirements on:

sales@indiaforging.com- soumil@indiaforging.com

Email:

- +91-98817-01007

- +91-253-2310221 / 2310275

Phone:

-

Aress High Duty Forgings Pvt. Ltd.

Address:

- E-27, MIDC, Malegaon, Sinnar, Nashik - 422103

Factory:

-

Unit No. 3, 1st Floor, Shivneri,

Next to Ramdas Colony Garden,

Canada Corner, Nashik - 422005